Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Wiki Article

Just How an Optical Fibre Diameter Analyser Boosts Quality Assurance in Fibre Manufacturing

The integration of an Optical Fibre Diameter Analyser into Fibre production procedures stands for a considerable improvement in quality assurance methodologies. By supplying real-time, accurate measurements of Fibre sizes, this modern technology resolves the essential requirement for uniformity in manufacturing criteria. With its capability to promptly determine deviations and timely corrective procedures, the analyser not only improves item reliability yet also adds to overall operational performance. As markets significantly prioritize top quality and compliance, comprehending the complete impact of such technologies becomes crucial. What ramifications could this have for the future of Fibre manufacturing?

Significance of Fibre Diameter Dimension

Precise dimension of Fibre Diameter is critical in the field of optical Fibre technology, as it directly influences the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter ensures that the optical homes are maintained within specified resistances, which is essential for optimum signal stability.Variations in Fibre Diameter can cause boosted losses because of scattering and modal diffusion, affecting the high quality of data transmission. In high-speed communication systems, such disparities can cause considerable deterioration of signal quality, bring about information errors and reduced efficiency. Additionally, consistent Fibre Diameter is important for compatibility with connectors and splicing modern technologies, which are important parts of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing heavily count on precise Diameter dimensions to make sure compliance with sector criteria. By executing robust measurement techniques, suppliers can boost item reliability, lessen waste, and enhance total system performance. Therefore, the importance of Fibre Diameter measurement can not be overemphasized, as it acts as a foundation in the advancement of optical Fibre innovation and its applications in modern-day communication networks.

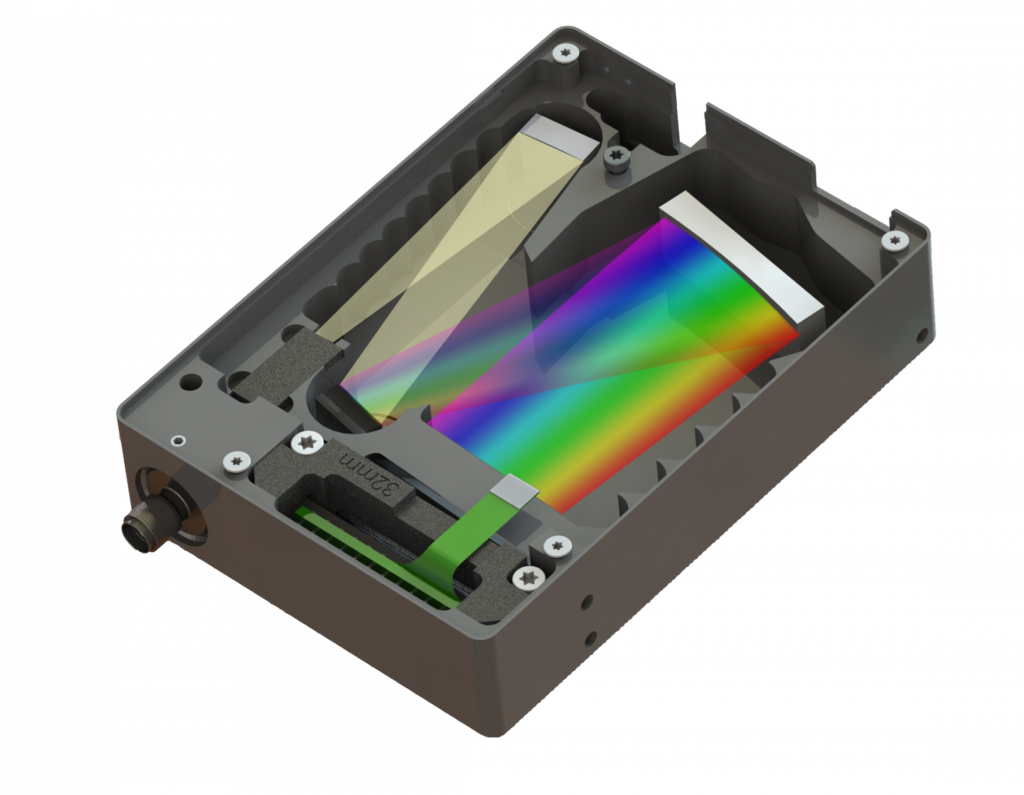

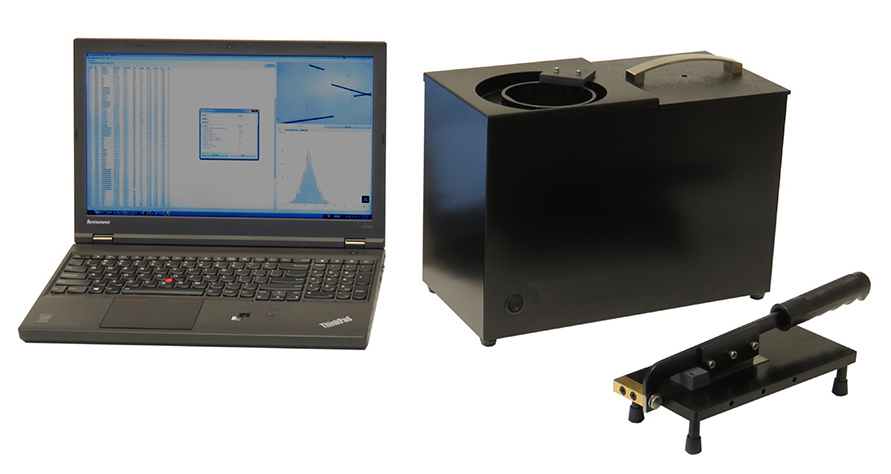

Just How the Analyser Functions

The efficient dimension of Fibre Diameter depends on sophisticated logical techniques that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser innovation and progressed image processing algorithms to precisely analyze the Diameter of fibres as they are createdOriginally, a laser light beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this shadow using high-resolution cams placed purposefully along the production line. The captured pictures are after that refined in real-time to establish the Fibre's Diameter with exceptional accuracy.

The system makes use of innovative formulas that make up numerous factors, including variations in light intensity and environmental problems, to enhance measurement reliability. It can spot minute modifications in Diameter, such as changes that may happen during the manufacturing process.

In addition, the analyser can taking care of numerous fibers all at once, raising throughput without endangering precision. By offering instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays an essential role in keeping rigid quality assurance requirements, making sure that the end product meets sector requirements and consumer demands.

Advantages of Real-Time Tracking

While conventional techniques of keeping an eye on Fibre Diameter frequently include taxing post-production checks, real-time monitoring substantially boosts the efficiency and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This positive strategy permits suppliers to recognize variances in Fibre Diameter as they take place, as opposed to waiting until production is complete to assess high qualityBy Get More Info continuously gauging the Diameter throughout production, suppliers can guarantee that the fibers meet rigorous specs, bring about minimized variability and enhanced uniformity. Real-time tracking additionally enables prompt corrective actions to be taken, decreasing waste and avoiding malfunctioning fibers from entering the supply chain.

In addition, this innovation promotes enhanced data collection and evaluation, giving insights into production patterns and possible locations for imp source improvement. Such data-driven decision-making empowers makers to maximize procedures and keep high requirements of top quality control.

Additionally, real-time monitoring fosters a culture of constant enhancement within the manufacturing setting. Staff members are extra involved when they can see the effect of their job in real-time, bring about enhanced accountability and a commitment to excellence. Overall, the implementation of real-time monitoring systems in optical Fibre manufacturing translates to superior item top quality and raised consumer complete satisfaction.

Effect on Production Efficiency

Implementing optical Fibre Diameter analysers dramatically boosts manufacturing effectiveness by improving the manufacturing process. These tools promote continual tracking of Fibre Diameter, permitting makers to find variances in real-time. By identifying inconsistencies promptly, manufacturing lines can be changed rapidly, minimizing downtime and reducing the chance of creating defective items.Moreover, the integration of these analysers right into the production workflow makes it possible for much better source allowance. With accurate Diameter measurements, drivers can enhance material use, guaranteeing that sources are not lost on flawed fibers. This precision additionally contributes to much less rework and junk, eventually decreasing production prices.

The automation offered by optical Fibre Diameter analysers lowers reliance on hand-operated evaluations, which are prone and usually lengthy to human mistake. Therefore, workers can concentrate on more critical tasks, improving total efficiency.

In addition, the data produced from these analysers can educate process enhancements and promote better decision-making. By examining trends in Fibre Diameter variants, manufacturers can carry out aggressive measures to improve manufacturing strategies and maintain consistent high quality. In recap, optical Fibre Diameter analysers play a vital duty in enhancing production effectiveness, causing better output and enhanced earnings.

Instance Researches and Success Stories

Across various industries, situation research studies highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One famous instance is a leading telecoms firm that encountered challenges like it with inconsistent Fibre sizes, bring about increased rejection prices. By integrating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre measurements, leading to a 30% reduction in problems and considerable expense savings.

Moreover, a research organization focusing on sophisticated materials used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capability to supply detailed understandings into Fibre uniformity enabled the advancement of innovative materials with better performance attributes.

These success stories highlight the crucial function of optical Fibre Diameter analysers in enhancing high quality control, boosting production effectiveness, and driving innovation across varied sectors.

Conclusion

In final thought, the Optical Fibre Diameter Analyser plays a critical function in improving quality control within Fibre production. As shown via numerous instance researches, the analyser verifies necessary for accomplishing remarkable product quality in Fibre production.

The application of optical Fibre Diameter analysers permitted for strict top quality control, guaranteeing that the generated fibres fulfilled exacting industry requirements.In verdict, the Optical Fibre Diameter Analyser plays a pivotal function in boosting quality control within Fibre manufacturing.

Report this wiki page